What's your pain threshold when it comes to building a house from scratch?

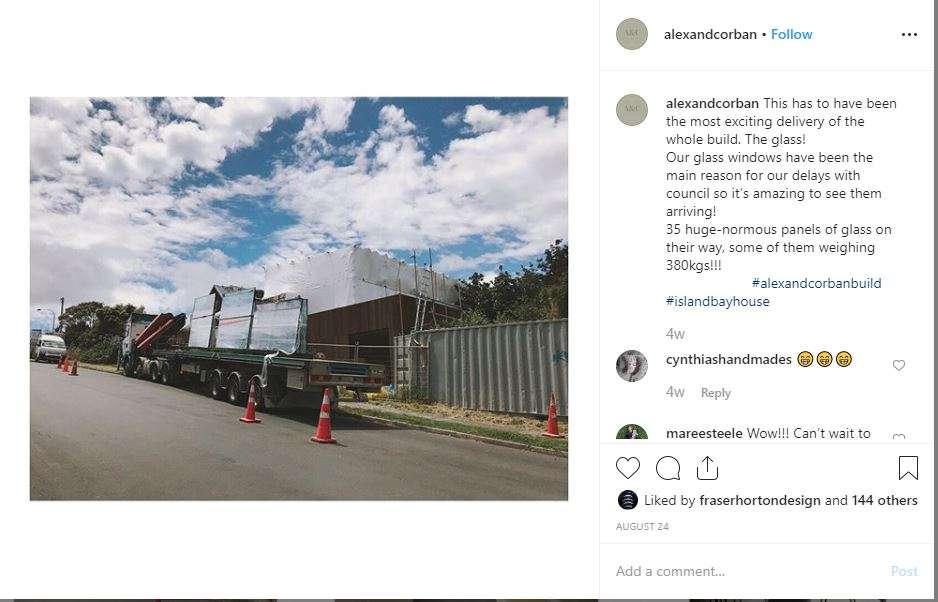

For Aucklanders Alex and Corban Walls it could be wrapping their new build in 35 glass panels that weigh 380kg each.

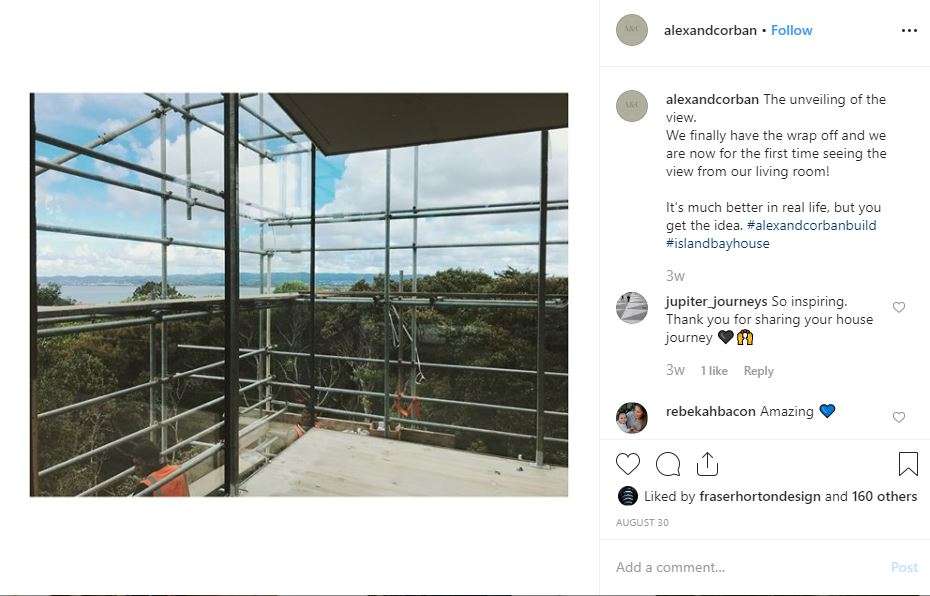

The couple, who are past winners of The Block NZ, are in the middle of building their dream home in Island Bay, in Auckland's North Shore.

The glass panels are the centrepiece of the design.

Start your property search

They reach to 3.2m high, and are by 2.4m wide to give the couple floor to ceiling views from the house into the bush reserve next door.

“It’s about taking in the views,” says Corban. “We also want a view out to our swimming pool and the best thing for pool safety is that you see in your day-to-day life.”

Engineer Corban was happy with how the 13.3 tonne glass design construction turned out, but getting there was a slow process. The innovative house design with glass wall stretching to such dramatic heights used the best high performance glass in the world, manufactured here in New Zealand.

He said the glass keeps the heat in the house and is key to the energy-efficient design of the house.

“In a real world you would get better insulating and performance from glass than you would from a fully-insulated wall.”

A glass wall is also cost-effective, low maintenance and visually appealing, Corban says, although, in this case, not quite as cost effective as they’d hoped. The couple estimates an 18-month process to receive a Auckland Council consent approval for the innovative design added about $350,000 more to the build, as cost of construction and submitting re-designs ballooned (they’re not counting the mental toll).

“The building code standard in New Zealand, from an international standard, our houses are absolutely rubbish. They are built poorly, design poorly and no one seems to care about it. All we were trying to do is to have a house far better constructed than what the building code requires.”

The Walls were keen to use innovative materials to achieve a warm, dry and energy efficient forever home, using cross laminated XLam timber, a sustainable locally manufactured timber to replaces steel or steel-reinforced concrete structural materials.

Corban’s comments were echoed by speakers at the recent Auckland World Green Building Week. Shawn McIsaac from architectural engineering company Oculus is bringing energy-efficient buildings to New Zealand, but says the company is stymied by current Building Code.

For example, new materials imported from overseas have to have a ten-year-old track record to be used in a structure, he says.

He said it was hard to explain innovative systems and methods used overseas and was frustrated at the resistance of council who were tied to the code.

“There are people in the industry who are interested in helping. The challenge is to bring people in to translate what we want to use into New Zealand building code.”

This was the Walls’ experience, explaining the ins and outs of the design to five different assessors who were unfamiliar with the innovative materials and systems.

“If you get a consenting officer who has never seen this material before they will make you jump through so many hoops,” Corban says.

Auckland Council’s premium building consent manager Sally Grey, also speaking at the Green Building Week event said Auckland had 45,000 homes less than needed and those consents were a priority.

“We can receive an application with nothing sustainable in it at all and we will still approve it because it meets the regulations,” she said at the event.

However, focusing on sustainability is “definitely on the agenda” Grey said.

Ministry of Business Innovation and Employment, along with Standards NZ, have a review under way of Building Code standards, slated for June 2020 release, which will include updating performance standards for New Zealand.